Tefla has begun experimenting with digital twin modelling, which creates virtual replicas of construction sites to improve planning and reduce risk. (Tefla)

South Africa’s efforts to modernise its construction and engineering sectors will take a major step forward in December when EastC Technocentric Varsity leads a high-level vocational exchange with partners in China.

Running from December 5 to 9, the programme is part of China’s Belt and Road Initiative (BRI) and focuses on improving South Africa’s technical training capacities, especially in robotics, automation, welding and digital modelling.

The exchange follows EastC’s recent visit to Deyang Installation Technician College and China Machinery Construction Corporation, where South African delegates toured training centres and observed how advanced technology is reshaping global construction industries. EastC (formerly Ekurhuleni Artisans and Skills Training College) has become a leader in hands-on artisan training through its long-standing partnership with China.

One of the biggest local beneficiaries of EastC’s training pipeline is Tefla Group, a civil engineering firm in Kempton Park that has absorbed more than 1,000 EastC-trained artisans over the past three years. The company’s workforce includes welders, riggers, machine operators and technicians with exposure to modern training systems not yet widely available in South Africa.

According to Doctor Chauke, head of human resources at Tefla Group, the impact has been significant.

“The integration of more than 1,000 EastC-trained artisans has strengthened our operations. It has improved our productivity, allowed us to meet project timelines more efficiently and raised our quality standards. We have also introduced strict safety training and monitoring to ensure every artisan meets our safety requirements,” he said.

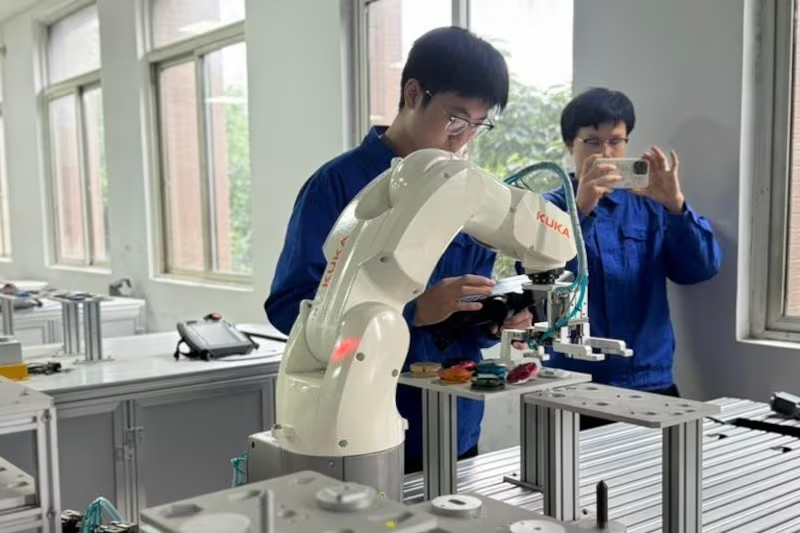

Skills gained from the EastC–China partnership are helping Tefla adopt new technologies in its construction projects. Robotics, in particular, has proved valuable.

“Among the new skills introduced through the partnership, robotics is the most immediately useful for us,” Chauke said. “Automated bricklaying and concrete dispensing help us work more efficiently and reduce human error.”

Tefla has also begun experimenting with digital twin modelling, which creates virtual replicas of construction sites to improve planning and reduce risk.

“We have launched digital twin pilot projects to simulate construction processes. The trials help us identify problems early and improve accuracy,” Chauke said. “We are also working with Chinese partners to test automated machinery and robotics on selected sites.”

As South Africa pushes toward industrial modernisation, Tefla expects to need more digitally focused skills in the coming years.

“We anticipate a rise in demand for digital project management skills,” Chauke said. “Tefla plans to invest in upskilling its workforce so we are aligned with new technologies and national development goals.”

While EastC graduates arrive with strong theoretical knowledge, their transition to real construction sites can be challenging.

“Graduates bring solid foundations, but they lack experience in managing real conditions such as tight deadlines, complex terrain and working in teams under pressure,” Chauke said.

To support the transition, Tefla has created a structured feedback system for EastC.

“We have a continuous feedback mechanism with EastC. It covers technical skills, problem-solving ability, adaptability and on-site behaviour. This helps ensure training stays aligned with industry needs,” Chauke said.

He emphasised deeper co-operation between training institutions and the construction industry will be essential as technology continues to evolve.

“We believe a joint training committee between EastC and industry would help identify the skills needed in the sector. Collaboration will ensure artisans are prepared for modern construction environments,” he said.

With youth unemployment high, Tefla sees itself playing an important role in creating opportunities for young people.

“Addressing youth unemployment requires industry commitment,” Chauke said. “Companies must offer vocational training and apprenticeships that give young artisans real hands-on experience.”

Tefla plans to continue increasing the number of EastC graduates it takes on, especially as the China training exchange expands capacity.

“Hiring skilled graduates is a priority for us. The expanded China programme will broaden the pool of qualified artisans we can employ,” he said.

Chauke said Tefla is committed to helping shape a technologically capable workforce that can meet the country’s infrastructure needs for years to come.

“We see our role as bigger than filling jobs today,” he said. “By investing in new technologies and continuous training, we are helping build a modern, skilled and competitive workforce for South Africa.”

The upcoming China–South Africa vocational exchange is expected to strengthen the efforts by accelerating skills development, expanding training opportunities and supporting companies such as Tefla that are committed to creating jobs and preparing young artisans for the future.